We use cookies to make your experience of our website better. Some of the cookies we use are essential for parts of the site to operate and have already been set. Find out more about the cookies we use and how to block or delete cookies here. By continuing to browse this site, you are agreeing to our use of cookies.

30-42m³ Giga Vitesse Forage Wagon

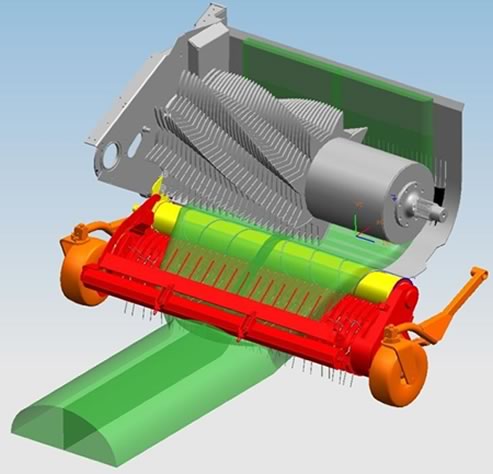

High-performance silage wagons are facing increasing demands with regard to higher efficiency, and when in competition with forage harvesters. As well as this, low drag resistance and low power requirement are called for when using professional forage wagons. The Strautmann Giga-Vitesse with its new conveying unit (Continuous Flow System) provides an almost unrivalled product for contractors and large businesses. This forage wagon is setting standards with regard to optimum loading, low power requirement and cost effectiveness.

The Giga-Vitesse, which benefits from the Continuous Flow System, is continuing the successful path which Strautmann has pursued since the introduction of the previous Giga-Vitesse (with no Continuous Flow System). A high-performance conveying assembly with a unique cutting unit, together with a solid body and a variety of chassis types for most different conditions have gained an excellent reputation over the years.

The Giga-Vitesse 01 range features a 2m camless pick-up, whilst the 02 range has the wider 2.25m campless pick-up, which means that in fields where grass has been poorly raked and left in wide swathes, and also around headlands and corners, drivers will find efficient pick-up much easier.

- Loading capacity according to DIN of 30 – 42m³

- Continuous Flow System accelerator drum

- Double benefit

- Spiral rotor with tine plates

- 45 double sided knives "01" series (35mm theoretical chop length)

- 44 double sided knives "02" series (35mm theoretical chop length)

- Power required from 96/130 kW/HP

- 2m camless pick up on "01" series

- 2.25m camless pick up on "02" series

|

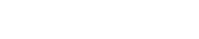

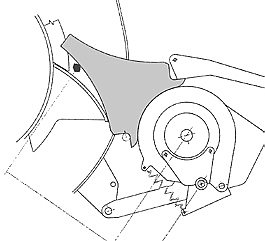

Continuous Flow System Due to the interaction of the different components, the Continuous Flow System unit ensures excellent loading performance and a low power requirement. The pick-up, Continuous Flow System roller, rotor and double-cut cutting unit are optimally matched to each other. This results in an excellent cutting quality and power efficient drive, saving time and money. |

|

|

Low power requirement The newly developed pick-up and the Continuous Flow System drum spreads out and disperses the swathe and feeds it over the entire width of the rotor and the cutting unit. The rotor, which is mounted 100mm higher, conveys the pre-wilted green fodder through the shortened conveyor duct into the cargo space, thus saving energy and reducing the power requirement by approx. 10%. |

|

|

Full width filling Thanks to the Continuous Flow System roller spreading the forage over the whole rotor width, the material is loaded into the cargo space over its entire loading space. We measured 10% more weight per cubic metre. The Continuous Flow System gives more weight than the competitors at the same capacity, making the tonnage capacity more important than the cargo space volume. |

|

|

High Performance A better filling spread also affects acreage performance. The areas to be harvested can be cleared quicker and the fodder is moved faster to the clamp. After all, time is money. |

|

|

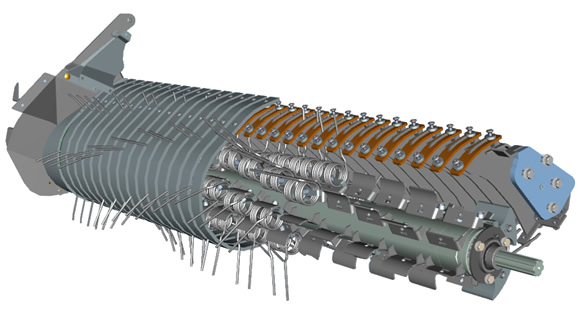

Optimum adaptation to ground contours Due to the design of the Continuous Flow System drum, the pick-up is at a very shallow angle, such that the pressure exerted on the feed rollers is very low, which enables the pick-up to better adapt to the contours of the ground. Furthermore, the green fodder is continuously and gently picked up due to the V-shaped helical arrangement of the pick-up tines. Tines are always picking up, but the V-shape means not all tines are touching the ground at the same time, preventing power peaks. |

|

|

Protection of drives Due to the homogeneous and continuous flow of material, the Continuous Flow System conveying unit runs very smoothly and consistently, meaning there are hardly any peak loads. And if there are no peak loads, the complete drive unit will be free from excessive forces ensuring a long service life of the conveying unit and therefore of the entire forage wagon. |

|

|

Longer service life of knives As the Continuous Flow System system spreads the grass evenly across the chopping rotor there is an even load on each of the knives. This means that knives wear more consistently and the sharpening interval is extended. On machines without a Continuous Flow System the central knives become blunt and reduce machine performance, this does not happen with a Strautmann Continuous Flow System pick-up. In addition, the knives are designed so that you are able to sharpen or replace only the blades that you need to, rather than all of the knives. |

|

|

|

|

Conventional conveying unit: The picked-up green fodder is delivered to the rotor without spreading-out effect. The rotor and the cutting unit are partially loaded. |

Continuous Flow System conveying unit: The picked-up green fodder is dispersed by the pick-up and the accelerator drum and fed to the rotor and cutting unit over the entire width. |

● Robust conveyor drum with helically arranged conveyor fins with Hardox tine plates ● Smooth operation, with no peak loads due to the helical rotor design ● One-sided, torsion-free drive of loading rotor due to low-maintenance gearbox ● Wide strippers with Hardox plates.

● Picking-up width of 2m (01 series) or 2.25m (02 series) ● 6 tine rows placed in a V-shape for smooth and even material flow ● Camless pick-up with very few wearing parts and low maintenance, compared to traditional Cam pick-up systems ● Plastic strippers for minimum tine wear.

● Distributor drum between the pick-up and rotor. ● Delivers fodder from pick-up to the rotor ensuring low hp requirement ● Even, full-width spread of material due to the helical welded layer, so the entire rotor width is utilised, keeping a minimal and constant load on the machine.

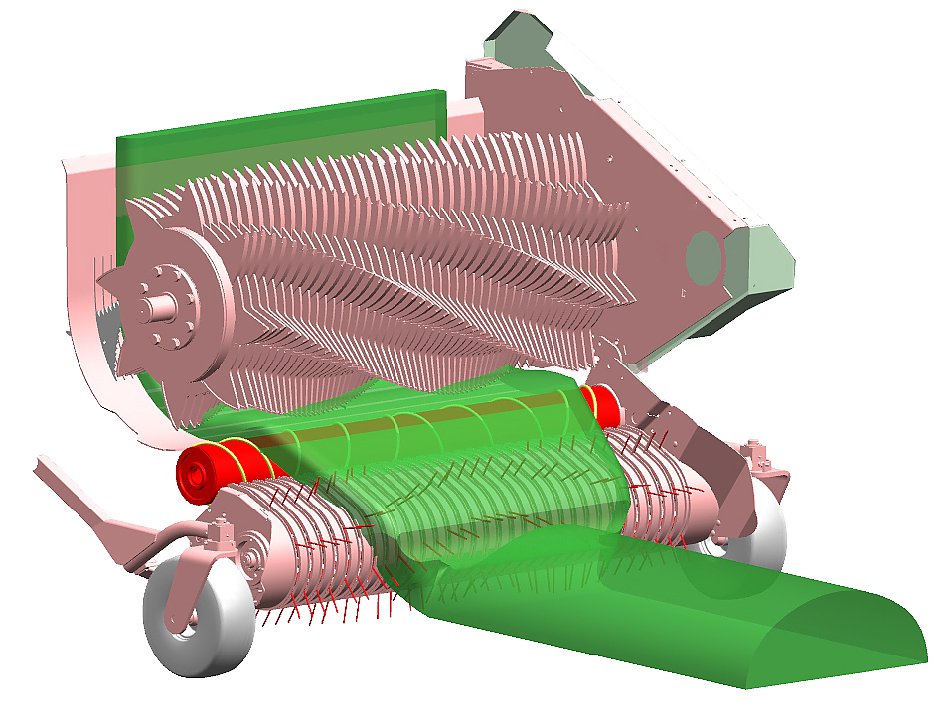

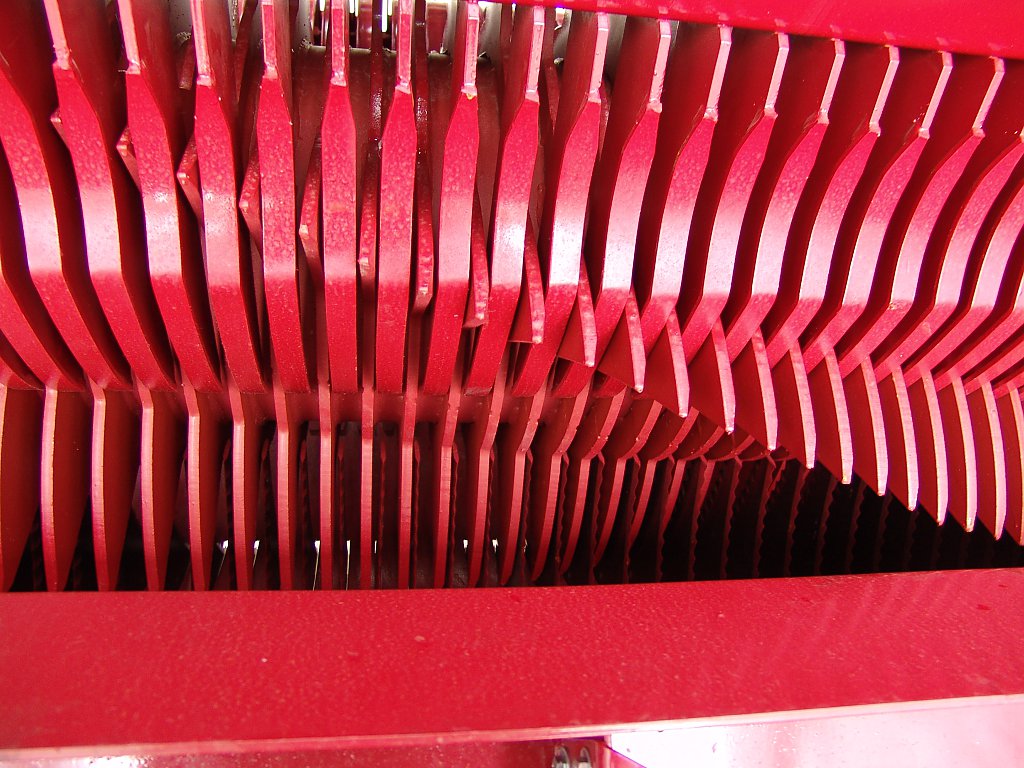

● Easy cutting cut due to optimum geometry between the cutting knives and rotor ● Knife protection without use of tools ● Turn-able knives due to double-sided blade for longer sharpening intervals and better cutting quality ● Individual knife protection with knife quick-change system ● 45 knives, on one level for a theoretical cutting/chop length of 35mm ● In case of shortened knives, readjustment of the entire knife bar via upper link ● Hydraulic extending and retracting of the entire knife bar.

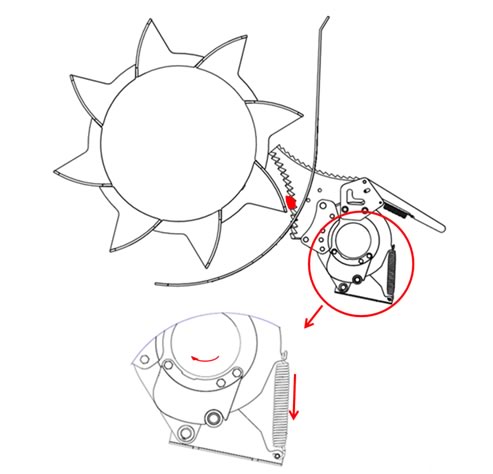

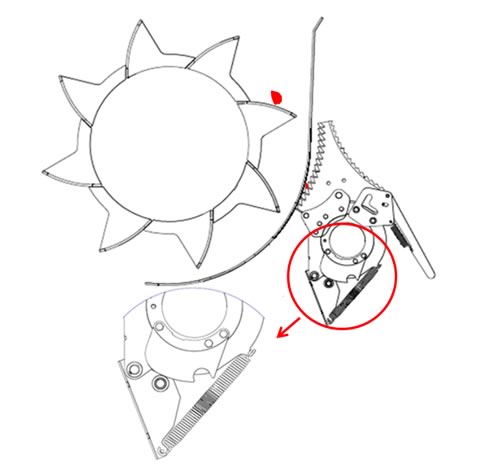

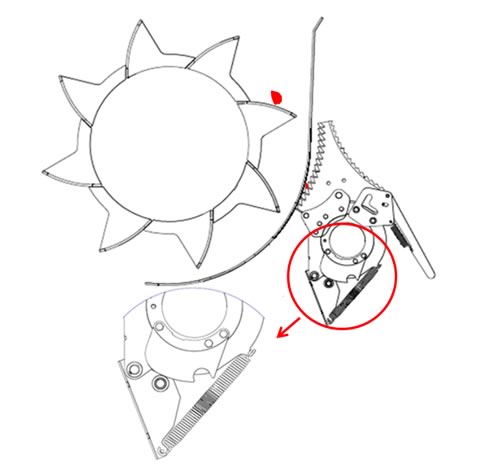

| Strautmann knife protection - in-work | Strautmann knife protection - safety break-back |

|

|

Instead of the knife being pressured into the rotor, the knife is set up with a cam clutch type system. The spot-on triggering, without the spring counter tension, means a foreign object will trigger the knife to spring out of the work position, thus only blunting or damaging one point on the blade. A conventional knife protection will cause the foreign object to travel the entire length of the blade before releasing it, blunting or braking a large portion of the blade.

● Easy cutting cut due to optimum geometry between the cutting knives and rotor ● Knife protection without use of tools ● Turn-able knives due to double-sided blade for longer sharpening intervals and better cutting quality ● Individual knife protection with knife quick-change system ● 44 knives, on one level for a theoretical cutting/chop length of 35 mm ● In case of shortened knives, readjustment of the entire knife bar via upper link ● Hydraulic extending and retracting of the entire knife bar.

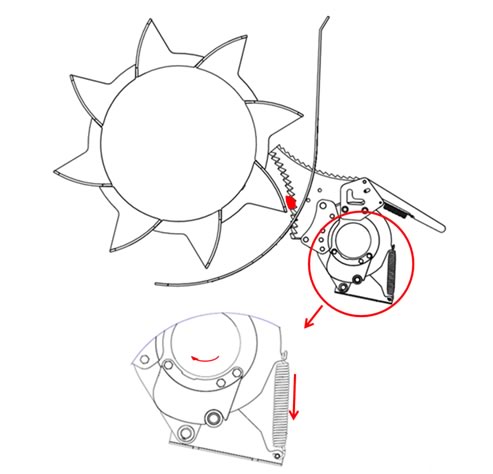

| Strautmann knife protection - in-work | Strautmann knife protection - safety break-back |

|

|

Instead of the knife being pressured into the rotor, the knife is set up with a cam clutch type system. The spot-on triggering, without the spring counter tension, means a foreign object will trigger the knife to spring out of the work position, thus only blunting or damaging one point on the blade. A conventional knife protection will cause the foreign object to travel the entire length of the blade before releasing it, blunting or braking a large portion of the blade.

A new cutting system with a cutting edge on both sides of the re-designed double sided blade, a 35mm chop-length is reliably guaranteed. The knives have a rapid-trigger protection function, which automatically retracts them from the chop channel if a foreign object is detected.

They then return automatically to their working position, maximising work-rates while minimising damage to the knives. Exact-cut is now standard on all Strautmann forage wagons, from the smaller Zelon through to the Magnon 10.

- 45 knives ‘Exact-Cut’ unit (Giga 01)

- 44 knives ‘Exact-Cut’ unit (Giga 02)

- 35mm theoretical cutting/chop length

- Tool-free knife change

The Giga-Vitesse 01 and 02 can be optioned with the new ‘Flex-Load’ pick-up which has six rows of plastic tines arranged in chevron formation. The pick-up is powered hydraulically for infinitely variable adjustment.

The Giga-Vitesse 01 and 02 can be optioned with the new ‘Flex-Load’ pick-up which has six rows of plastic tines arranged in chevron formation. The pick-up is powered hydraulically for infinitely variable adjustment.

- Less breakage of tines

- Minimised tine wear

- Change of tines in under a minute

- Tines flex to adapt to ground contours

- Gentle pick up for ground protection

- Less contamination of fodder

More information on the flex-load pick-up can be found here.

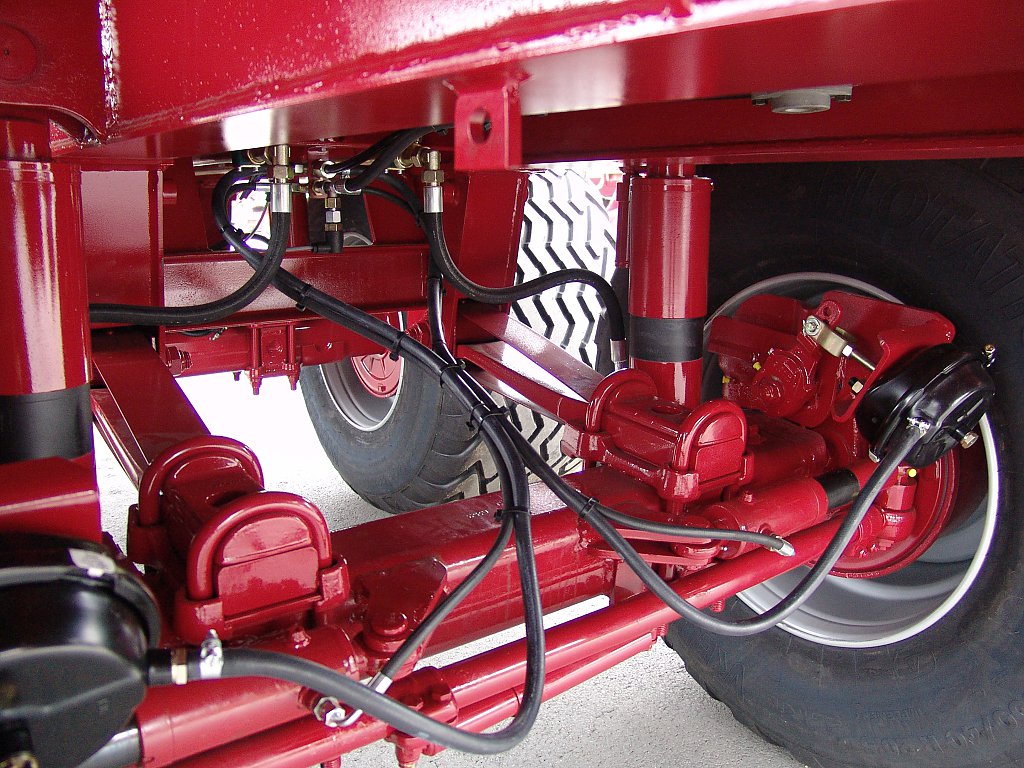

● Tandem axle assembly ● Spring-loaded tandem axle (40km/h) for optimum driving characteristics and easy towing ● Tandem steering where the rear axle freely follows the movement of the tractor and wagon. Optional: Active steering axle that utilises a second ball-joint on the drawbar which activates the rear axle as the tractor and wagon turns, helping prevent excessive tyre wear.

Optional additional pick-up guide roller behind the pick-up for permanent adaptation to the ground in case of deeper tractor tracks or heavily undulating ground.

- Solid body with continuous fixing supports

- Designed also for use as a maze trailer

- Without brackets and ropes above the cargo space (available as optional extras, though)

For traveling over silage clamps, all models are equipped with a hydraulic folding drawbar with two double-acting cylinders. A hydraulic drawbar suspension ensures an even smoother ride during road travel.

Transport floor chains made of solid square tubes welded to low-wear plate-link chains. These chains do not stretch as much as round steel chains and require less maintenance. The optional galvanised steel floor gives the vehicle more stability (standard on the 4401 model). ● Divided transport floor with 4 transport floor chains ● Hydraulic transport floor ● Automatic transport floor chain tightening ● Optional 2-stage feed motor ● Standard bumper buffer

The optional ISOBUS control offers the driver easy operation without having to familiarise themselves with a new control box. Of course, the ISO suitability also creates the option of operation via existing terminals on the premises or on the tractor. Thus, interesting advantages of the valuable control terminals can be transferred to the machine use.

- Solid tailgate

- Two double-acting cylinders

- Electrical pressure switch as level indicator

- Mechanical locking system

Integrated slip clutch avoids damage to the pick-up and the rotor tines

|

Solid tailgate (standard)

|

|

|

Effective dosing drums (optional)

|

|

|

Robust drive

|

|

The Giga-Vitesse 01 models have a pick-up width of 2.00m with holding capacities of 57m³, 65m³, 72m³ and 80m³ (30-42m³ DIN)

- 57-80m³

- 2m camless pick up on “01” series

- 45 double-sided knives “01” series (35mm theoretical chop length)

- 4 floor chains

- From 130 hp

- Auto load

- ISOBUS controls

- 2 speed floor

- Hydraulic sprung drawbar

- Load lights

| Model No. | Description | Size |

| 25V5000050 | Giga Vitesse 3201 Wooden Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 57m3 (30m3 DIN) |

| 25V5010051 | Giga Vitesse 3601 Wooden Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 65m3 (34m3 DIN) |

| 25V5010050 | Giga Vitesse 3601 Steel Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 65m3 (34m3 DIN) |

| 25V4960051 | Giga Vitesse 4001 Wooden Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 72m3 (38m3 DIN) |

| 25V4960050 | Giga Vitesse CFS 4001 Steel Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 72m3 (38m3 DIN) |

| 25V4980050 | Giga Vitesse CFS 4401 Steel Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 80m3 (42m3 DIN) |

The wider 2.25m 02 pick-up means that in fields where grass has been poorly raked and left in wide swathes, and also around headlands and corners, drivers will find efficient pick-up much easier. The new rotor design further enhances the action of the Continuous Flow System by ensuring an even grass density at the outside of the chopper rotor which in turn densely fills the full width of the wagon.

In this new 02 model range, the conveying unit has been completely revised. The camless pick-up with 6 V-shaped tine rows is equipped with plastic strippers preventing early tine wear and improving smooth running.

The guide wheels have also been modified: they can remain in position during road travel and do not need to be retracted. Furthermore, their height adjustment has been made easier, and hence the operating height of the pick-up is now also more easily adjusted. Unique to Strautmann forage wagons is the Continuous Flow System roller which is situated between the pick-up and the rotor. It ensures grass is presented evenly and spread across the full width of the chopper rotor. The new chopper rotor features 8 helical rows of feeder tines which convey the material into the cargo space, across a width of 1600mm. Side augers, 250mm in width, have been incorporated at either end of the rotor. They reliably convey the material from the outsides of the pick-up inwards to the rotor tines. Thus, the working width of the rotor reaches an overall width of 2100mm. The rotor drive has also been revised: on the right-hand side, an oil-bath gearbox transmits the tractor power to a planetary gear set integrated in the rotor. Thus, the speed is only reduced at the rotor, which prevents high torques in the power train. In summary, the new model Giga-Vitesse 3602 now has a 2.25m pick up, new side augers and 44 knives feeding a 1.54m rotor to give a 35mm theoretical chop length. Other features remain the same except for a small increase (5cm) in transport width - to 2.86m - due to the wider pick-up.

| Model No | Description | Size |

| 25V5010053 | Giga Vitesse 3602 Steel Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 65m3 (34m³ DIN) |

| 25V4960052 | Giga Vitesse 4002 Steel Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 72m3 (38m³ DIN) |

| 25V4980052 | Giga Vitesse 4402 Steel Floor (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 80m3 (42m³ DIN) |

|

Short Cut Forage / Dosage Wagon Giga-Vitesse 01 Series |

|||||

|

|

|||||

|

Technical data |

|||||

|

Type |

|

GV 3201 |

GV 3601 |

GV 4001 |

GV 4401 |

|

Dimensions |

|||||

|

length |

m |

8,69 |

9,42 |

10,22 |

11,02 |

|

width / outer wheel width |

m |

2,55 / 2,81 |

2,55 / 2,81 |

2,55 / 2,81 |

2,55 / 2,81 |

|

height |

m |

4,00 |

4,00 |

4,00 |

4,00 |

|

Loading vol. acc. to DIN 11741 |

m³ |

30,0 |

34,0 |

38,0 |

42,0 |

|

with dosing unit |

m³ |

- |

32,0 |

36,0 |

40,0 |

|

Loading volume (medium compressed) |

m³ |

57,0 |

64,6 |

72,2 |

79,8 |

|

with dosing unit |

m³ |

- |

60,8 |

68,4 |

76,0 |

|

Tare weight at basic specification |

kg |

8600 |

9 |

9.4 |

9.9 |

|

with dosing unit |

kg |

- |

9.4 |

9.8 |

10.3 |

|

Perm. max. weight |

|||||

|

- with low drawbar (up to 40 km/h) |

kg |

22.000 |

22.000 |

22.000 |

22.000 |

|

- with hydraulic chassis |

kg |

- |

- |

24 |

24 |

|

- with tridem chassis |

kg |

- |

- |

- |

31 |

|

Power requirement |

kW/hp |

100 / 135 |

107 / 145 |

118 / 160 |

132 / 180 |

|

Dimensions with tyres |

710/50 R 26.5 |

710/50 R 26,5 |

710/50 R 26,5 |

710/50 R 26,5 |

|

|

Short Cut Forage / Dosage Wagon Giga-Vitesse 02 Series |

||||

|

|

||||

|

Technical data |

||||

|

Type |

|

GV 3602 |

GV 4002 |

GV 4402 |

|

Dimensions |

||||

|

length |

m |

9,42 |

10,22 |

11,02 |

|

width / outer wheel width |

m |

2,55 / 2,81 |

2,55 / 2,81 |

2,55 / 2,81 |

|

height |

m |

4,00 |

4,00 |

4,00 |

|

Loading vol. acc. to DIN 11741 |

m³ |

34,0 |

38,0 |

42,0 |

|

with dosing unit |

m³ |

32,0 |

36,0 |

40,0 |

|

Loading volume (medium compressed) |

m³ |

64,6 |

72,2 |

79,8 |

|

with dosing unit |

m³ |

60,8 |

68,4 |

76,0 |

|

Tare weight at basic specification |

kg |

9 |

9.4 |

9.9 |

|

with dosing unit |

kg |

9.4 |

9.8 |

10.3 |

|

Perm. max. weight |

||||

|

- with low drawbar (up to 40 km/h) |

kg |

22.000 |

22.000 |

22.000 |

|

- with hydraulic chassis |

kg |

- |

24 |

24 |

|

- with tridem chassis |

kg |

- |

- |

31 |

|

Power requirement |

kW/hp |

107 / 145 |

118 / 160 |

132 / 180 |

|

Dimensions with tyres |

710/50 R 26,5 |

710/50 R 26,5 |

710/50 R 26,5 |

|

Tim West, TW West Ltd, Rottingham

Tim West runs an agricultural contracting business which includes the cutting of 8000 acres of grass for silage. His fleet of forage machinery includes two forage wagons which give him flexibility in silage-making operations and enable better quality silage to be made at less cost.

Tim explains: "It started with just me and a round baler. Then bale wrappers came out and I bought one of them. So I needed someone to come and work with me and before I knew it, I'd employed someone. And the rest is history."

The business has grown and Mr West now employs a team of 8 full-time workers. Customers are predominantly dairy farmers and so the core services are the usual contracting jobs: silaging, slurry spreading, cultivations, fencing etc..