We use cookies to make your experience of our website better. Some of the cookies we use are essential for parts of the site to operate and have already been set. Find out more about the cookies we use and how to block or delete cookies here. By continuing to browse this site, you are agreeing to our use of cookies.

Verti-Mix Single, Double and Triple Auger

You want your business to grow - the Verti-Mix adapts to your growing needs.

Why use a Verti-Mix........

1, Excellent mixing quality - because only cows getting optimum nutrition are healthier and deliver higher milk yields.

2, Low power requirement - reducing your diesel consumption.

3, Flexibility - the Verti-Mix can adapt to your farm requirements.

4, Reliability - cows need feeding 365 days a year!

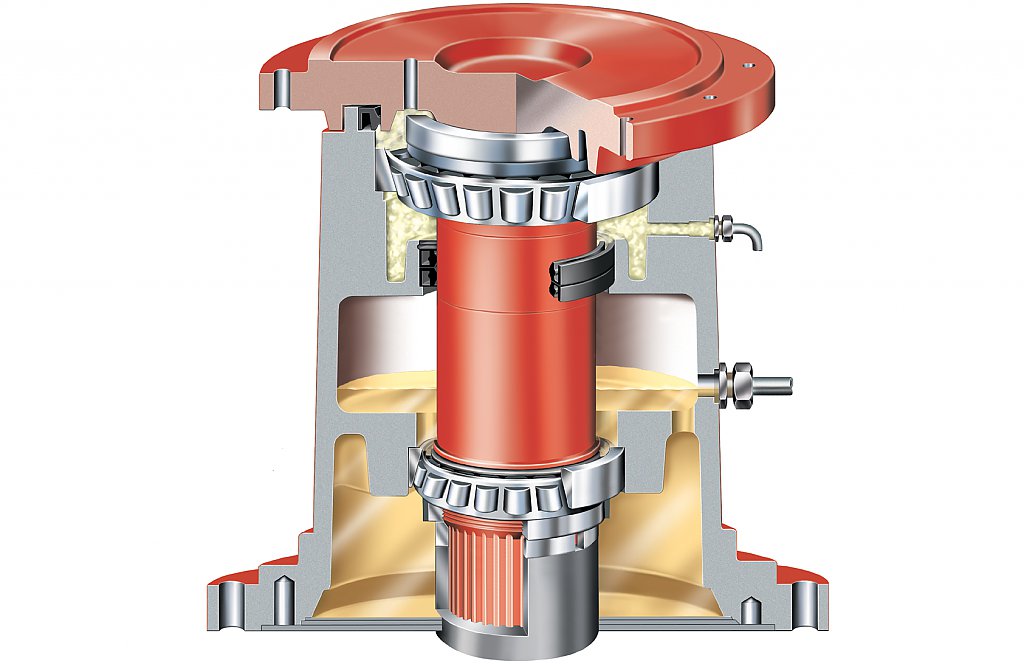

5, IMS (Intensive Mixing System) Auger – speeds up mixing time and so reduces labour and tractor time.

Be among those who benefit from our more than 20 years of experience in mixing technology and become one of Strautmann's 20,000 customers!

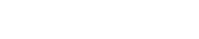

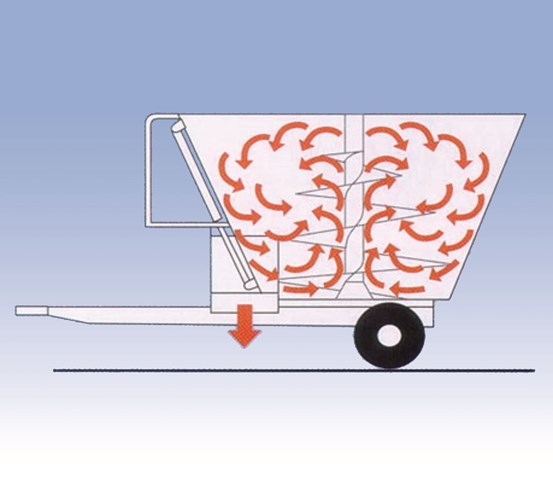

All Strautmann range of mixer wagons will allow farmers to save time and cut costs. A uniquely designed Intensive-Mix System (IMS) which improves the tumbling action, providing a homogeneous mix faster, whilst using less power and creating less wear.

International scientific studies have revealed that the efficiency in milk production can be increased many times over by the use of feed mixing wagons. Due to the mixing of individual components to a TMR (partial or total mixed ration), the animals can no longer select and thus take up the same feed makeup with every bite, which ensures optimum physiological care of the entire herd, regardless of the position of the individual animal in ranking.

All Verti-Mix mixer wagons can be fully configured to meet individual farm requirement.

First choose the capacity..... This should be chosen depending on the feed ration and number of cows per m3 when feeding once a day. Extensions ensure you can choose exactly the correct capacity for your feeding requirements.

Second choose your discharge...... A huge range of discharge options, ranging from side discharge, conveyor and rear discharge allowing the feed or bedding to be place exactly where required.

Third choose your controls...... The choice of preferred operating controls depends very much on the user.

Fourth choose your weighing device...... The weighing device is an integral component of the mixing wagon. Only an exact quantity of the individual ingredients ensures full use of the mixing wagon's cost effectiveness.

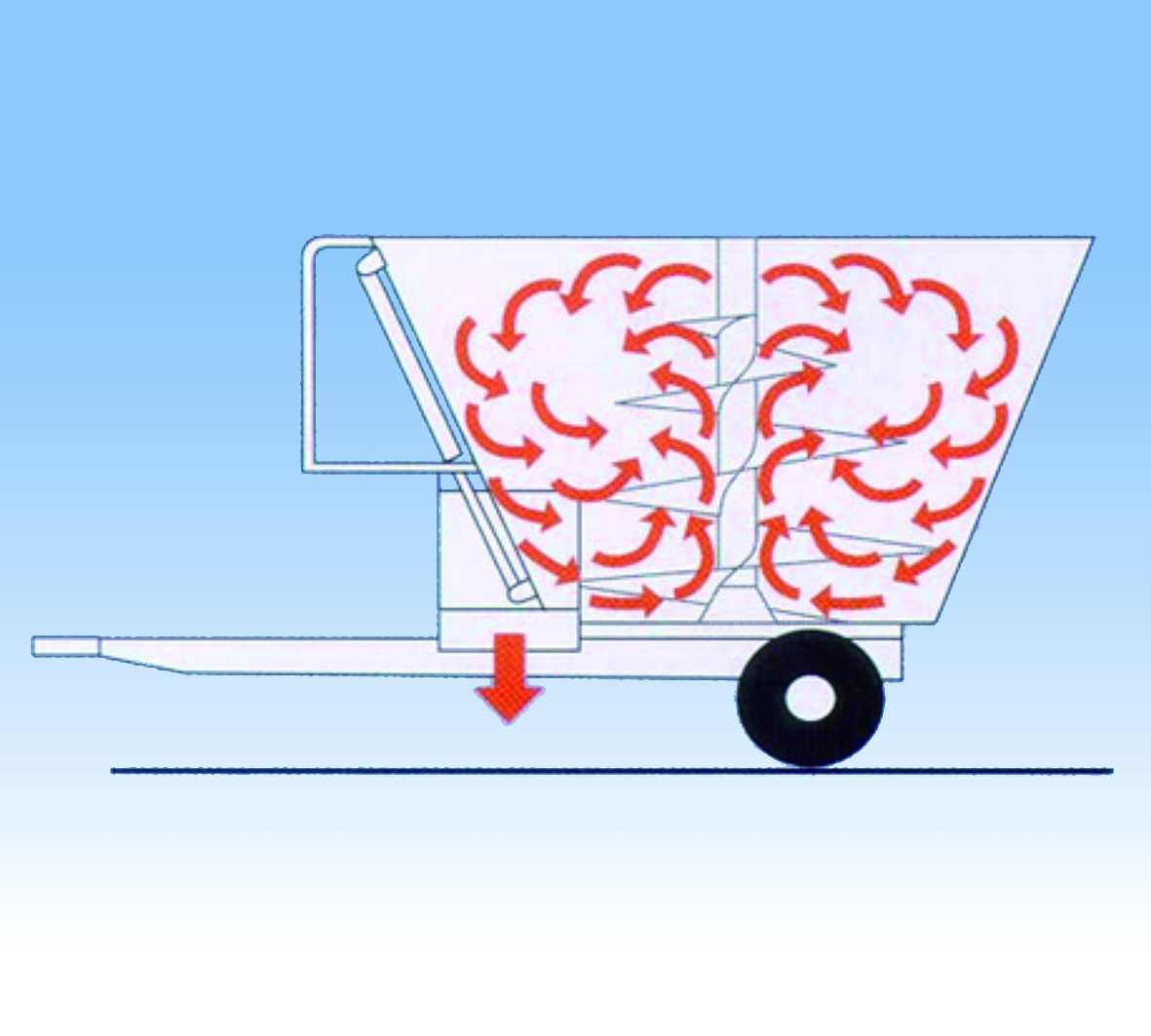

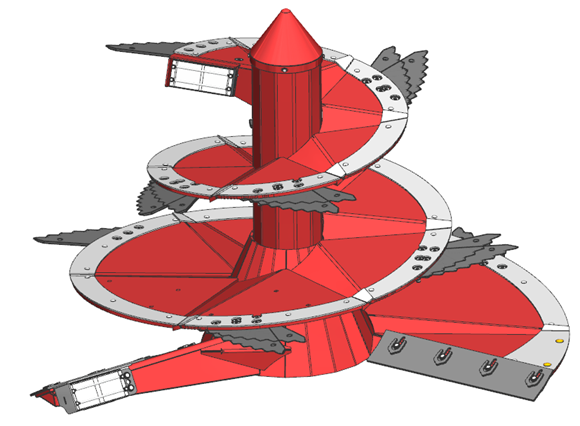

The heart of the Vario mixing auger is the very heavy duty and durable gearbox. Stability and long maintenance intervals are achieved by means of a large-sized pair of tapered roller bearings, double sealing and a large grease chamber.

Variability and strength for any purpose. Due to the patented knife adjustment system and the updated IMS auger design, the IMS mixing auger can be perfectly adapted to your specific conditions of use. The robust and low-maintenance angular gearbox ensures long service life even under challenging conditions.

All Strautmann mixer wagons now come fitted with an IMS auger as standard. Its stepped design enables a good mix to be achieved more quickly. This reduces the mixing time of each load, which due to the number of mixes each day, creates a saving on labour, wear and fuel over time.

The perfect harmonisation of mixing auger geometry and the distance to the container wall forms the basis for quick and homogenous mixing.

Longer term, machinery repair and replacement costs can be reduced by requesting the INNODUR stainless steel wear strip to be fitted to the leading edge of the auger. This is a replaceable part, further extending machine lifetime.

Highly effective magnetic separation of metallic foreign objects. The Strautmann magnetic system (optional extra) directly mounted at the mixing auger offers optimum health protection for your high-yield cows. The system is mounted such that it is in direct and close contact with the mixed fodder, thus working very effectively.

Manual counter cutters

Two manually adjustable counter-cutters enable the processing of larger quantities of long-fibre fodder such as round and square bales.

Hydraulic counter cutter

The optional two hydraulic counter-cutters can be directly adjusted from the driver seat.

A mineral feed funnel can be mounted at the mixing container on request. This makes it easier to fill in smaller quantities of fodder such as e.g. mineral feed or lime.

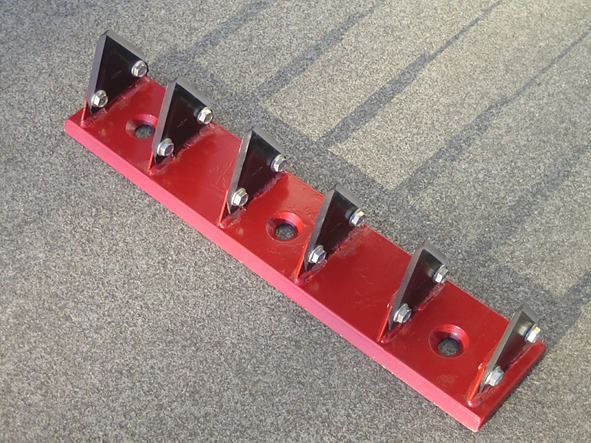

An optional row of cutting knives are available to assist with chopping root crops such as potato and beet.

Special knife options help you to adapt your IMS mixing auger to your requirements.

Depending on the application, you can select from a range of different hydraulic motors to give you different speeds.

Available with optional lights and optional rear view camera with monitor.

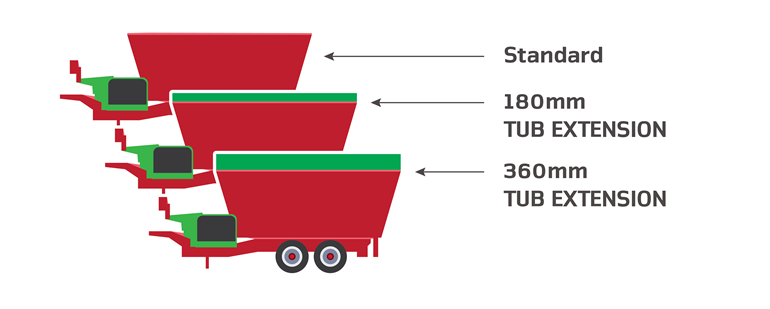

The patented container design at the top container edge provides the Strautmann mixing container with additional rigidity. It serves as a basis for variable container attachments helping you to adapt the capacity of the mixing container to your operational requirements. Two optional extensions with different heights enable you to flexibly adapt your Verti-Mix to your needs (180mm and 360mm).

Verti-Mix 1401

The 1401 Special is a 12m³ “no frills“ mixer, specified for the UK market. The mixer benefits from the same features as the rest of

the Strautmann range.

The 1401 Special is available with the option of 2 different tub extension sizes, giving the opportunity to increase the capacity up

to 14m3. Available with one or two doors, the 1401 Special can also be equipped with a direct hydraulic connection to tractor controlled discharge conveyor, enabling discharge over certain barriers.

● Usable mixing capacity of 12m³

● Front right-hand door

● Enclosed hay ring

● Single axle with hydraulic brake

● Wide angle PTO, PTM HL50 programmable weighing

● Direct hydraulic connection to the tractor

IMS - The "New Generation"

● Usable mixing capacity of 7.5 - 16.5 m³

● Expandable by 180 mm or 360 mm attachments

● Highest stability of the container due to patented embossing

● All components have been designed for maximum mixing capacity

Verti-Mix Double - Twice as good

The fodder mixing wagons of the Verti-Mix Double series particularly excel by their high mixing capacity, while maintaining compact dimensions. Based upon the single auger vertical mixers, which are known for their gentle and quick mixing, the Verti-Mix Double is equipped with 2 vertical IMS mixing augers. Apart from the quick preparation of larger fodder mixtures, the Verti-Mix Double models can particularly demonstrate their strengths in the powerful undoing of round and square bales.

● Usable mixing capacity of 12.0 - 30.5 m³

● Capacity expandable by 180 mm or 360 mm attachments

● All components have been designed for maximum capacity

● 50 - 180 cows per container filling

● Power required from 50 - 135 HP (37 - 100 kW)

Verti-Mix Double K - The easy-towing all-rounder

Preservation of the fodder structure, quick mixing, low wear, low maintenance costs, low power required and a slim design - these are the characteristics of today's classical 2-auger vertical mixers. Their disadvantage, however, is the fact that they cannot be equipped with large tyre sizes (22.5") without considerable influence on the machine height. And this is exactly where Strautmann comes in, with the design of the Verti-Mix Double K. This is the first fodder mixing wagon which, due to its special container design, combines the advantages of the classical vertical mixing wagons with those of the horizontal mixing wagons (slim design, large tyres beside the mixing container) in one machine.

● Usable mixing capacity of 13 - 21 m³

● Unique container shape for low design

● 50 - 150 cows per container filling

● Power required from 55 - 74 HP (41 - 54 kW)

Verti-Mix Triple - 3 IMS augers for better mixing

The three-auger mixers with three vertical mixing augers are also equipped with the proven and patented extension concept with container embossing for maximum stability and flexibility. These adaptable large-scale fodder mixing wagons are perfectly suitable for large and still growing dairy farms

● Usable mixing capacity of 28,5 m³ - 45,0 m³

● Capacity expandable by 180 mm or 360 mm attachments

● All components have been designed for maximum capacity

● 140 - 320 cows per container filling

In the case of side discharge, the asymmetrical position of the discharge openings ensures optimum fodder discharge which results in a loose, homogeneous swathe. The fodder is discharged at the optimum position at the fodder mixing wagon, relative to the flow of material in the container. No travelling over the fodder.

Variable conveyor speeds achieved by means of different motors or direct adjustability enable the fodder discharge width to be adapted as far as right up to directly in front of the feed fence. A unique lattice bar roller as return roller for the crossover conveyor prevents the fodder from piling up between the roller and the conveyor.

The cleaner and more germ-free the cubicle, the healthier the animals. The ideal litter materials are straw, peat, sawdust and lime. After the mixing process in the container has been finished, the litter is spread up to the head region of the cubicles via the drum – comfortably and reliably for maximum animal comfort and udder health. Only in combination with electrical operation.

Discharge in narrow dead-end feeding passages. For comfortable feeding even in narrow dead-end feeding passages, side doors behind the wheels are being used. The fodder is loosely discharged on one or both sides behind the wheels.

For preparation of premixes or central fodder discharge on the feeding table, Strautmann offers a rear centre discharge.

Variable conveyor speeds achieved by means of different motors or direct adjustability enable the fodder discharge width to be adapted as far as right up to directly in front of the feed fence. A unique lattice bar roller as return roller for the crossover conveyor prevents the fodder from piling up between the roller and the conveyor.

If the machine is equipped with a side discharge door, an additional conveyor can be mounted in front of the discharge door to fill higher troughs.

For higher troughs, a 1m long conveyor extension adjustable in height can be mounted at the side of the crossover conveyor.

Fodder-protecting discharge via adjustable side chutes. At the side discharge devices, adjustable chutes support the fodder discharge. The wheels do not roll over the discharged fodder. The side chutes can be equipped with an optional hydraulic actuating mechanism.

Additional benefit for your Verti-Mix by use as spreading equipment. A high-yield cow requires 2 kg of litter every day - more than 6t a month for 100 cows. Thanks to this optional extra equipment your Verti-Mix fodder mixing wagon can also be used for this type of work.

One double-acting connection for each function on the mixing wagon is required for operation via direct tractor connection. This type of operation is particularly useful if the mixing wagon is very rarely unhitched from the tractor or if the mixing wagon is only equipped with a side discharge (1 double-acting connection is required).

Regardless of the mixing wagon equipment, a double-acting control device is required on the tractor for operation via Bowden cables. This type of operation is particularly useful if older tractors are used in front of the mixing wagon, which are equipped with a small number of control devices. Standard switchgears are also operated via Bowden cables.

Just like for the operation via Bowden cables, a double-acting control device is required on the tractor for electrical operation, regardless of the mixing wagon equipment. Due to its compact dimensions and its light weight, customers who want to use the mixing wagon tractor also for other work on the farm from time to time, prefer this type of operation.

PTM HL 50

|

|

PTM Advance Super USB

|

|

PTM AV 70 - Radio remote control

|

|

Digi-Star EZ 2810

- Large 1.7" screen

- Pre-set weight function providing improved accuracy and management of loading and unloading

- Internal 'alarm and horn' alerting operator of approaching target pre-set weight

- Rotation counter/timer aiding the control of mixing time and processing

Digi-Star EZ 3610 V

- Programmable weighing device with data-transfer via data-key

- 150 recipes

- 99 components

- 6 digits each 43mm high

- Identification of the components as running text

- w 262mm x h 183mm x d 127mm

Digi-Star CCT 500 - Wireless Controller

- Additional display only together with EZ 3610 only (wireless)

- Easy view from inside the cab

- Simple touch screen display

- Control indicator display

- Slim compact design

For weighing device (here with AV50)