We use cookies to make your experience of our website better. Some of the cookies we use are essential for parts of the site to operate and have already been set. Find out more about the cookies we use and how to block or delete cookies here. By continuing to browse this site, you are agreeing to our use of cookies.

36–52m³ Magnon Forage Wagon

The Magnon series is aimed primarily at agricultural businesses and contractors . The top of the Strautmann range of forage wagons are equipped with a number of new features including a Moving Front Wall, as well as Flex-Load pick-up and Exact Cut.

The Magnon 8 is a compact machine with a loading capacity of 36m³ to 44m³ (DIN). It has a smaller ‘external’ footprint to other wagons with similar DIN.

The Magnon 10 is the big brother wagon with a loading capacity of 40m³ to 52m³ (DIN).

If you're interested in demonstrating a Strautmann Forage Wagon, please click here.

The hydraulically moving front wall provides the Magnon with increased capacity. When the wagon starts filling, the front wall is in a vertical position towards the rear of the wagon, but when chopped grass builds up and pushes against the tailgate sensor the front panel moves forward, in three stages, to increase capacity. This ensures maximum density is achieved throughout the loading operation.

The hydraulically moving front wall provides the Magnon with increased capacity. When the wagon starts filling, the front wall is in a vertical position towards the rear of the wagon, but when chopped grass builds up and pushes against the tailgate sensor the front panel moves forward, in three stages, to increase capacity. This ensures maximum density is achieved throughout the loading operation.

The movement of the front wall provides an additional 4.5 m³ loading capacity when the cargo space is completely filled. When discharging, the front wall is hydraulically moved to the rear of the machine to assist with unloading.

This enables the Magnon 8 to have a smaller ‘external’ footprint to other wagons with similar DIN making it the ideal machine for agricultural businesses and contractors who are dependent on compact dimensions.

|

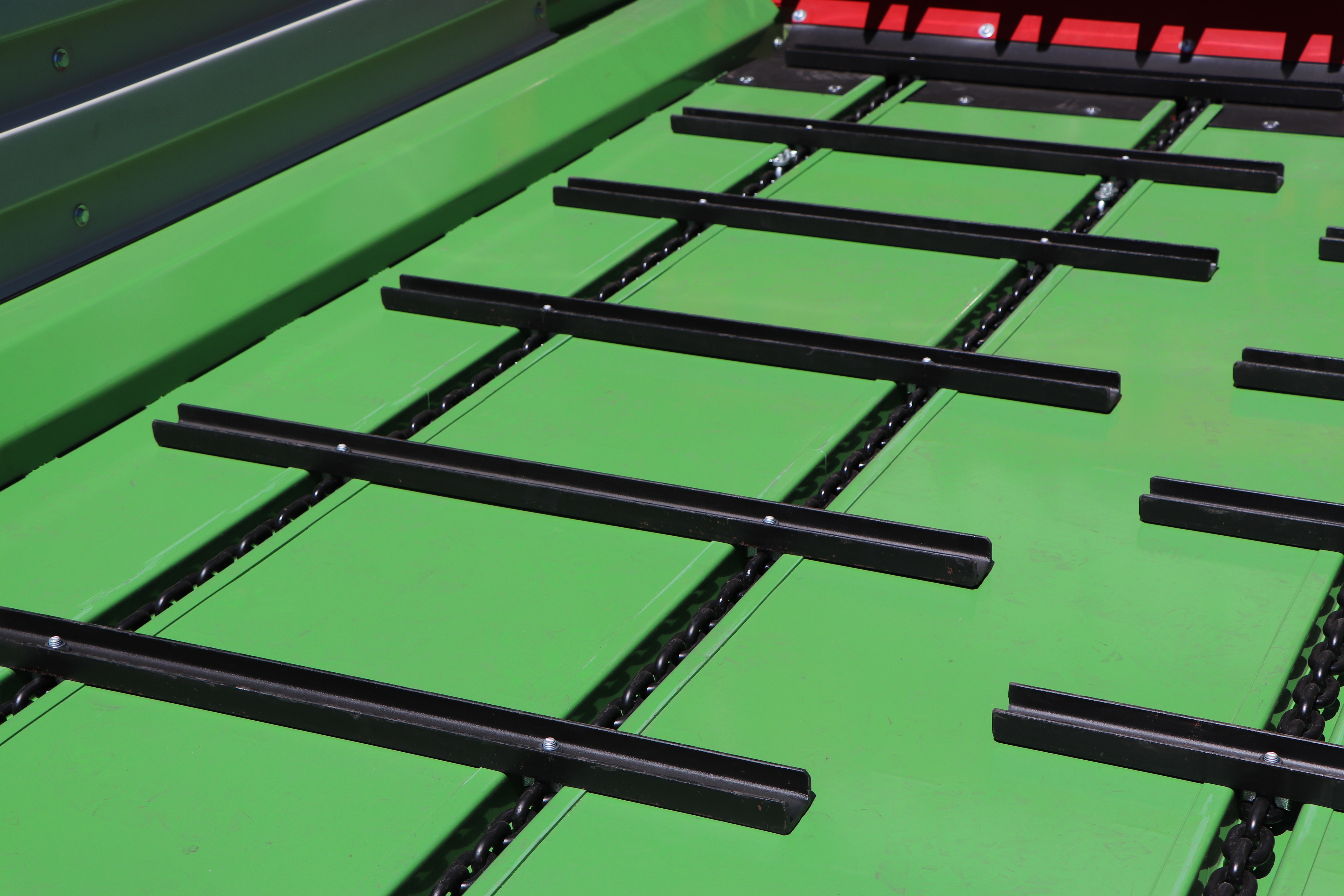

Continuous Flow System Due to the interaction of the different components, the Continuous Flow System unit ensures excellent loading performance and a low power requirement. The pick-up, Continuous Flow System roller, rotor and double-cut cutting unit are optimally matched to each other. This results in an excellent cutting quality and power efficient drive, saving time and money. |

|

|

Low power requirement The newly developed pick-up and the Continuous Flow System drum spreads out and disperses the swathe and feeds it over the entire width of the rotor and the cutting unit. The rotor, which is mounted 100mm higher, conveys the pre-wilted green fodder through the shortened conveyor duct into the cargo space, thus saving energy and reducing the power requirement by approx. 10%. |

|

|

Full width filling Thanks to the Continuous Flow System roller spreading the forage over the whole rotor width, the material is loaded into the cargo space over its entire loading space. We measured 10% more weight per cubic meter. The Continuous Flow System gives more weight than the competitors at the same capacity, making the tonnage capacity more important than the cargo space volume. |

|

|

High Performance A better filling spread also affects acreage performance. The areas to be harvested can be cleared quicker and the fodder is moved faster to the clamp. After all, time is money. |

|

|

Optimum adaptation to ground contours Due to the design of the Continuous Flow System drum, the pick-up is at a very shallow angle, such that the pressure exerted on the feed rollers is very low, which enables the pick-up to better adapt to the contours of the ground. Furthermore, the green fodder is continuously and gently picked up due to the V-shaped helical arrangement of the pick-up tines. Tines are always picking up, but the V-shape means not all tines are touching the ground at the same time, preventing power peaks. |

|

|

Preservation of drive line Due to the homogeneous and continuous flow of material, the Continuous Flow System conveying unit runs very smoothly and consistently, meaning there are hardly any peak loads. And if there are no peak loads, the complete drive unit will be free from excessive forces ensuring a long service life of the conveying unit and therefore of the entire forage wagon. The rotor is powered via an oil-bath gearbox to the rotor. The high (1000rpm) speed through the drive line is reduced to the rotor for both maximum torque and preservation of the drive line. |

|

|

Longer service life of knives As the Continuous Flow System spreads the grass evenly across the chopping rotor there is an even load on each of the knives. This means that knives wear more consistently and the sharpening interval is extended. On machines without a Continuous Flow System system the central knives become blunt and reduce machine performance, this does not happen with a Strautmann Continuous Flow System pick-up. In addition, the knives are designed so that you are able to sharpen or replace only the blades that you need to, rather than all of the knives. |

|

|

Double-roller crop press The Innovative crop press roller has been designed to optimise forage flow into the Flex-Load pick-up. It is standard throughout the Magnon range. The larger diameter, double roller crop press with a slip-proof profile ensures optimal flow into the mechanically powered Flex-Load pick-up. In addition, a guide roller mounted behind the pick-up is available as an optional extra for optimum adaptation to the ground |

|

The Magnon series is equipped with a new ‘Flex-Load’ pick-up which has six rows of plastic tines arranged in chevron formation. The pick-up is powered hydraulically for infinitely variable adjustment.

The Magnon series is equipped with a new ‘Flex-Load’ pick-up which has six rows of plastic tines arranged in chevron formation. The pick-up is powered hydraulically for infinitely variable adjustment.

- Less breakage of tines

- Minimised tine wear

- Change of tines in under a minute

- Tines flex to adapt to ground contours

- Gentle pick up for ground protection

- Less contamination of fodder

More information on the flex-load pick-up can be found here.

- Picking-up width of 2.25m

- 6 helically arranged rows of plastic tines for reduced contamination of fodder.

- Low maintenance camless pick-up with very few wearing parts, compared to traditional 'cam' pick-up systems.

A new cutting system with a cutting edge on both sides of the re-designed double sided blade, a 35mm chop-length is reliably guaranteed. The knives have a rapid-trigger protection function, which automatically retracts them from the chop channel if a foreign object is detected.

A new cutting system with a cutting edge on both sides of the re-designed double sided blade, a 35mm chop-length is reliably guaranteed. The knives have a rapid-trigger protection function, which automatically retracts them from the chop channel if a foreign object is detected.

They then return automatically to their working position, maximising work-rates while minimising damage to the knives. 44 double sided 'Exact-Cut' knives are fitted to the Magnon 8, whilst 48 double-sided 'Exact-Cut' knives are fitted to the Magnon 10.

- Easy cutting cut due to optimum geometry between the cutting knives and rotor

- Knife protection without use of tools

- Turn-able knives due to double-sided blade for longer sharpening intervals and better cutting quality

- Individual knife protection with knife quick-change system

- Readjustment via threaded spindles for worn knives

- Hydraulic extending and retracting of the entire knife bar

|

|

|

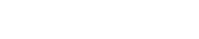

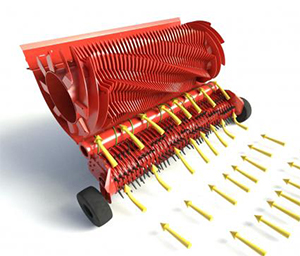

The Forage box is 2.25m wide and consists of four round steel chains (10 x 31 mm) embedded in the steel platform floor. They each have a breaking strain of 13t. The entire platform is powder-coated for protection against corrosion.

The Forage box is 2.25m wide and consists of four round steel chains (10 x 31 mm) embedded in the steel platform floor. They each have a breaking strain of 13t. The entire platform is powder-coated for protection against corrosion.

The body has been designed for maximum interior width to increase transport capacity. The continuous side panels with the reinforced side posts give the vehicle stability. A large 6-foot access door with a folding ladder always ensures safe entry into the vehicle.

The body has been designed for maximum interior width to increase transport capacity. The continuous side panels with the reinforced side posts give the vehicle stability. A large 6-foot access door with a folding ladder always ensures safe entry into the vehicle.

Safe transport of the loaded material can be guaranteed with the optional cargo space cover. This solution is hydraulically operated via a swivel drive and can be easily operated from the tractor seat. Available on the Magnon 10 models only.

Safe transport of the loaded material can be guaranteed with the optional cargo space cover. This solution is hydraulically operated via a swivel drive and can be easily operated from the tractor seat. Available on the Magnon 10 models only.

A boogie tandem chassis is standard on the two smaller Magnon 8 models (370 and 410) and a hydraulic tandem chassis is standard on the Magnon 8 450 model smaller Magnon 10 430 and 470 models. It is optional on the 370 and 410 Magnon 8 models. All models come with 4 x 710/50 R26.5 wheels as standard.

However, the hydraulic tandem chassis can be fitted with wheels up to 800/45 R 30.5, thus enabling 30.5" tyres. Larger wheels offer increased stability which is ideal for sloping ground.

However, the hydraulic tandem chassis can be fitted with wheels up to 800/45 R 30.5, thus enabling 30.5" tyres. Larger wheels offer increased stability which is ideal for sloping ground.

- Hydraulic tandem chassis standard on all Magnon 8 450 models, and on Magnon 10 430 and 470 models

- Optimum driving comfort due to distribution of load on all wheels

- Stable driving characteristics even when traversing hills

A tridem chassis with an axle load of 27t, active steering and lifting axle is an option on the Magnon 10 series. Hydraulic active steering is standard on largest Magnon 10 530 model.

A tridem chassis with an axle load of 27t, active steering and lifting axle is an option on the Magnon 10 series. Hydraulic active steering is standard on largest Magnon 10 530 model.

- Electro-hydraulic forced steering axle system for the first and third axle optional on all Magnon 10 models

- Integrated lift axle

- Standard on the Magnon 530 model with a gross vehicle weight rating of 34t

The Strautmann ISOBUS control with its intuitive menu navigation and various automatic functions is part of the standard equipment. For maintenance work, the drawbar and the cutting unit can be easily operated from the outside. A 5.7" control terminal can be offered as an option if an ISOBUS-compatible tractor is not available.

For travelling over silage clamps, all models are equipped with a hydraulic folding drawbar with two double-acting cylinders. A hydraulic drawbar suspension ensures an even smoother ride during road travel.

For travelling over silage clamps, all models are equipped with a hydraulic folding drawbar with two double-acting cylinders. A hydraulic drawbar suspension ensures an even smoother ride during road travel.

In order to increase the periods of use of the forage wagons, the Strautmann forage wagon offers the option to be used as fully-fledged forage transport wagon. For this purpose, basic standard equipment is provided for these vehicles, such as:

In order to increase the periods of use of the forage wagons, the Strautmann forage wagon offers the option to be used as fully-fledged forage transport wagon. For this purpose, basic standard equipment is provided for these vehicles, such as:

- A solid tailgate with mechanical locking mechanism

- Open cargo space without body brackets or ropes

- Hydraulically folding front panel

|

Solid tailgate (standard)

|

|

|

|

Effective dosing drums (optional)

|

|

Robust drive

|

|

Information related to the Magnon 8 models are featured below:

- 68-84m³ (36-44m³ DIN)

- 2.25m 'Flex-Load' camless pick-up

- 'Exact-cut' 44 double sided knives (35mm theoretical chop length)

- 4 floor chains

- Steel floor

- From 150hp

- Autoload

- ISOBUS controls - 5" terminal optional

- 2 speed floor

- Hydraulic sprung drawbar

- Load lights

| Model No | Description | Size |

| 25V6000050 | Magnon 8 370 (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 68m3 (36m3 DIN) |

| 25V6120050 | Magnon 8 410 (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 76m3 (40m3 DIN) |

| 25V6140050 | Magnon 8 450 (4 x 710/50 R26.5 wheels on hydraulic tandem steering axle, 10 stud) | 84m3 (44m3 DIN) |

Information related to the Magnon 10 models are featured below:

- 78-97m3 (42-52m³ DIN)

- 2.25m 'Flex-Load' camless pick-up

- 'Exact-cut' 48 double sided knives (35mm theoretical chop length)

- 4 floor chains

- Steel floor

- From 190hp

- Autoload

- ISOBUS controls - 5" terminal optional

- 2 speed floor

- Hydraulic sprung drawbar

- Load lights

- Auto lock of steering axle in reverse

| Model No | Description | Size |

| 25V5210050 | Magnon 10 430 (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 78m3 (42m3 DIN) |

| 25V5230050 | Magnon 10 470 (4 x 710/50 R26.5 wheels on tandem steering axle, 10 stud) | 86m3 (46m3 DIN) |

| 25V5250050 | Magnon 10 530 (4 x 710/50 R26.5 wheels on hydraulic tridem steering axle, 10 stud) | 97m3 (52m3 DIN) |

|

Strautmann Magnon 8 |

||||

|

|

||||

|

Technical data |

||||

|

Type |

|

Magnon 8 370 without DO/with DO |

Magnon 8 410 without DO / with DO |

Magnon 8 450 without DO / with DO |

|

length |

m |

9.25 | 9.90 | 10.53 |

|

width / outer wheel width |

m |

2.81 | 2.81 | 2 .81 |

|

height |

m |

3.90 | 3.90 | 3.90 |

|

Cargo space height |

m |

2.08 | 2.08 | 2.08 |

|

Cargo space width |

m |

2.25 | 2.25 | 2.25 |

|

Cargo space length |

m |

6.25 | 7.17 | 7.80 |

|

Dead weight, standard equipment |

kg |

10,100 | 10,700 | 11,300 |

|

Gross vehicle weight rating |

kg |

20,000 | 20,000 | 24,000 |

|

Power required from |

kW/HP |

110/150 | 125/170 | 140/190 |

|

Loading capacity, medium compaction |

m3 |

67 | 74 | 81 |

|

Loading capacity according to DIN 11741 |

m3 |

36 |

40 |

44 |

|

Conveying unit type |

|

Rotor |

Rotor |

Rotor |

|

Number of knives |

pcs |

44 |

44 |

44 |

|

Picking-up width of pick-up |

m |

2.25 |

2.25 |

2.25 |

|

Theoretical cutting length |

mm |

35 |

35 |

35 |

|

Strautmann Magnon 10 |

||||

|

|

||||

|

Technical data |

||||

|

Type |

|

Magnon 430 without DO/with DO |

Magnon 470 without DO / with DO |

Magnon 530 without DO / with DO |

|

length |

m |

9.90 | 10.53 | 11.78 |

|

width / outer wheel width |

m |

2.81 | 2.81 | 2 .81 |

|

height |

m |

3.90 | 3.90 | 3.90 |

|

Cargo space height |

m |

2.08 | 2.08 | 2.08 |

|

Cargo space width |

m |

2.40 | 2.40 | 2.40 |

|

Cargo space length |

m |

7.17 | 7.80 | 9.05 |

|

Dead weight, standard equipment |

kg |

11,100 | 11,700 | 13,600 |

|

Gross vehicle weight rating |

kg |

24,000 | 24,000 | 34,000 |

|

Admissible tongue load |

kg |

4,000 | 4,000 | 4,000 |

|

Axle load |

kg |

20,000 | 20,000 | 30,000 |

|

Power required from |

kW/HP |

140/190 | 154/210 | 176/240 |

|

Loading capacity, medium compression |

m3 |

74/78 | 82/86 | 93/97 |

|

Loading capacity according to DIN 11741 |

m3 |

42/40 |

46/44 |

52/50 |

|

Conveying unit type |

|

Rotor |

Rotor |

Rotor |

|

Number of knives |

pcs |

48 |

48 |

48 |

|

Picking-up width of pick-up |

m |

2.25 |

2.25 |

2.25 |

|

Theoretical cutting length |

mm |

35 |

35 |

35 |