We use cookies to make your experience of our website better. Some of the cookies we use are essential for parts of the site to operate and have already been set. Find out more about the cookies we use and how to block or delete cookies here. By continuing to browse this site, you are agreeing to our use of cookies.

Verti-Mix Self Propelled

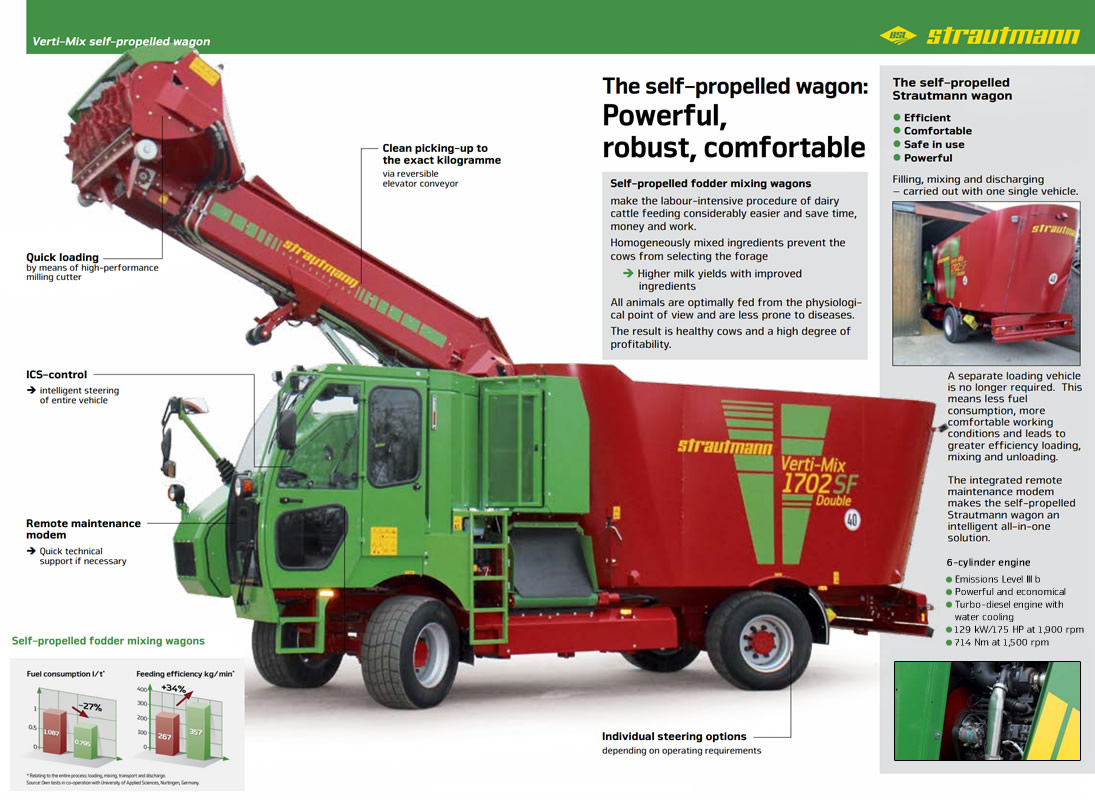

Verti-Mix - The self-propelled model: Powerful, robust, comfortable

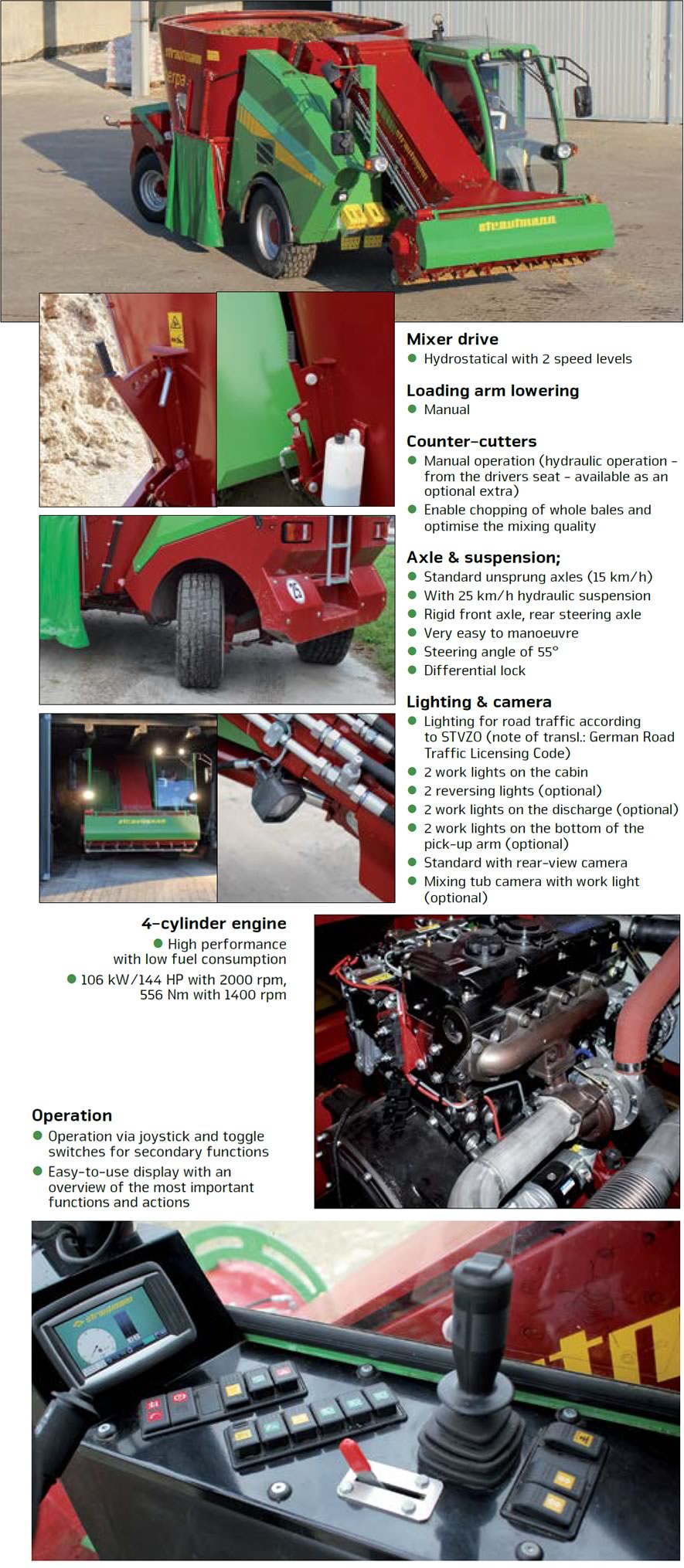

The Verti-Mix SF and Sherpa are the result of Strautmann's experience in fodder mixing technology for over the last 20 years. The Strautmann Vario2 mixing auger technology substantially contributes to increasing the productivity of modern dairy farms.

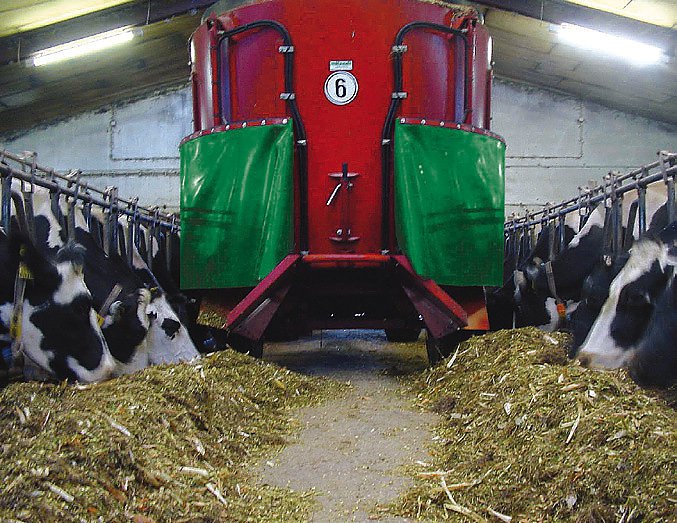

Self-propelled fodder mixing wagons make the labour-intensive dairy cattle feeding procedure much easier thus saving time and labour. Homogeneously mixed ingredients prevent the cows from selecting the fodder. Higher milk yields are achieved with improved ingredients distributed evenly. All animals are optimally fed from the physiological point of view and less prone to diseases which leads to healthy, long-living cows and a high degree of effectiveness.

● Usable mixing capacity of 11 - 20 m³. ● Picking-up and feeding with one machine. ● Optimum protection of fodder and ideal cut surfaces. ● Accurate preparation of feed ration. ● Smooth cut surface shape. ● Maximum efficiency. ● 6-cylinder engine for maximum power and low consumption, 4-cylinder engine for the Verti-Mix Sherpa.

International scientific studies have revealed that the efficiency in milk production can be increased many times over by the use of feed mixing wagons. Due to the mixing of individual components to a TMR (partial or total mixed ration), the animals can no longer be selective and thus take up the same feed make-up with every bite, which ensures optimum physiological care of the entire herd, regardless of the position of the individual animal in ranking.

All Verti-Mix SF mixer wagons can be fully configured to meet individual farm requirement.

First, choose the capacity..... This should be chosen depending on the feed ration and the number of cows per m3 when feeding once a day.

Second, choose your discharge...... A huge range of discharge options, ranging from side discharge, conveyor and rear discharge allowing the feed or bedding to be placed exactly where required.

Elevator

- Mounted at the center of the back of milling cutter for quick, gentle material flow

- Smooth running, low-maintenance elevator conveyor made of rubber

- Hydraulically powered

- Infinitely variable speed adjustment

- Reversible for exact picking-up of components

Fodder picking-up & transport

- Clean picking up right to the bottom

- Fast running elevator conveyor for clean feed flow

- Optimum parabolic trajectory from the elevator into the mixing containerAutomatic cutter arm lowering for quick and effortless working

High-performance milling cutter

- 2 m in width

- 114 knives efficiently take the fodder out of the silo

- Helical arrangement of knives for maximum picking-up performance with clean cut surface

- 60 cranked and 54 straight knives

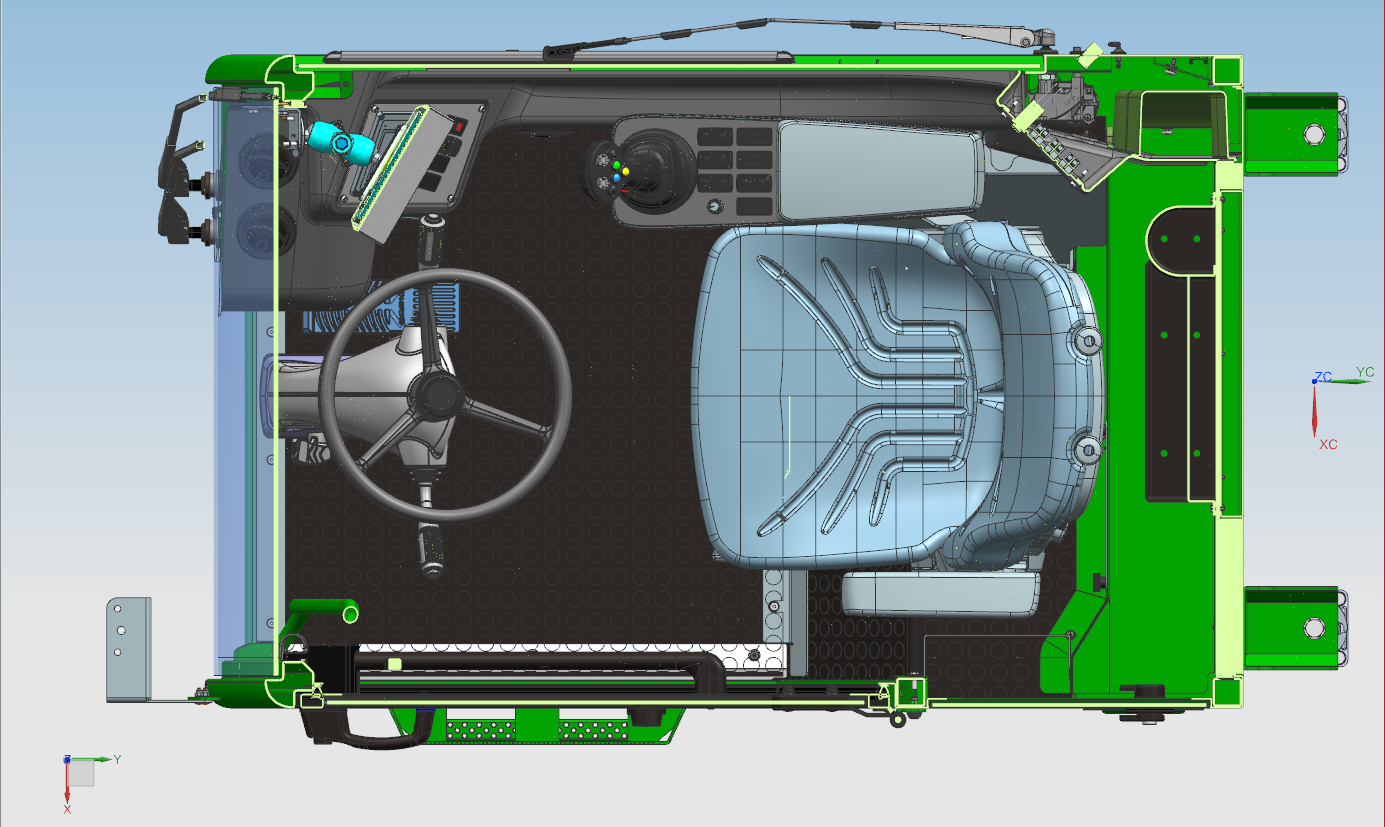

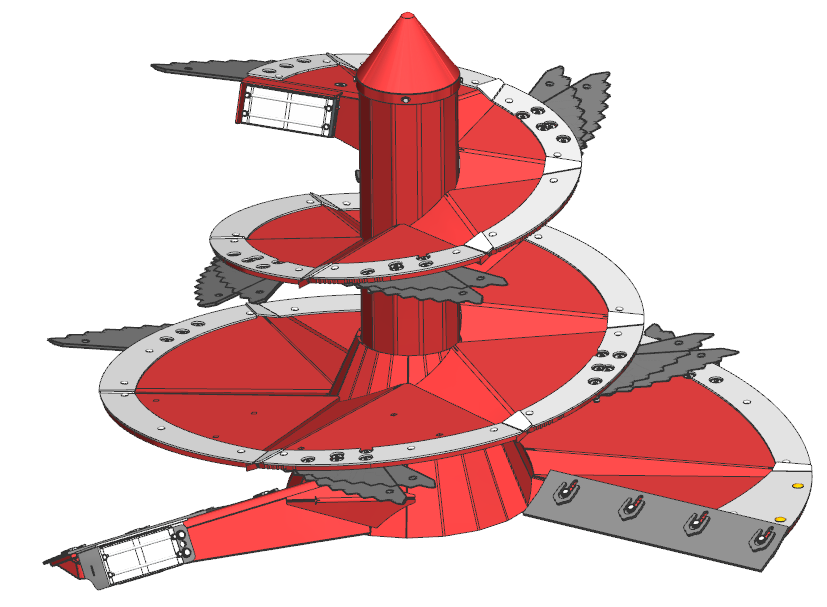

Variability and strength for any purpose. Due to the patented knife adjustment system and the updated IMS auger design, the IMS mixing auger can be perfectly adapted to your specific conditions of use. The robust and low-maintenance angular gearbox ensures long service life even under challenging conditions.

All Strautmann mixer wagons will now come fitted with an IMS auger as standard. Its stepped design enables a good mix to be achieved more quickly. This reduces the mixing time of each load, which due to the number of mixes each day, creates a saving on labour, wear and fuel over time.

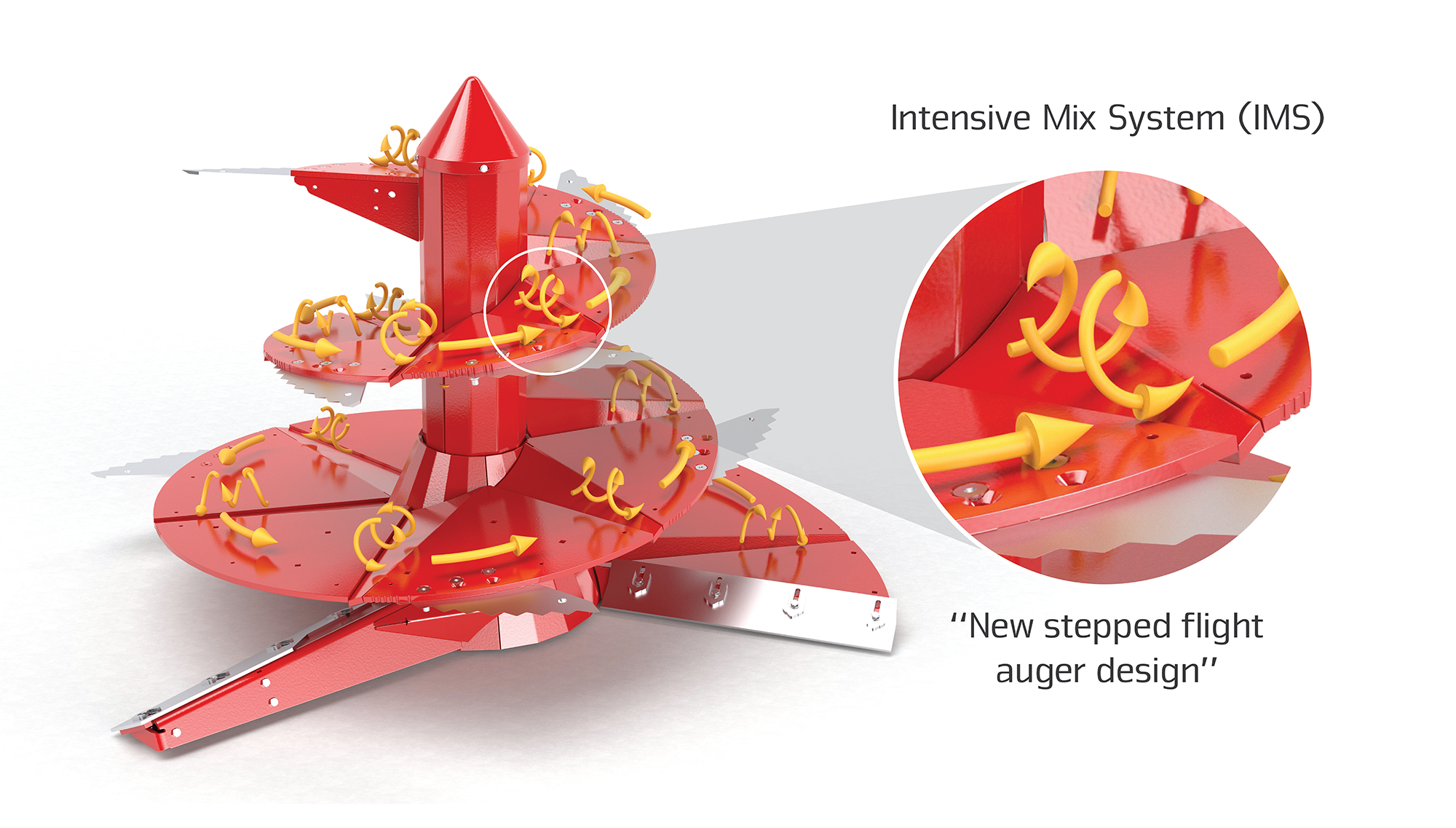

The heart of the Vario mixing auger is the very heavy duty and durable gearbox. Stability and long maintenance intervals are achieved by means of a large-sized pair of tapered roller bearings, double sealing and a large grease chamber.

Longer term, machinery repair and replacement costs can be reduced by requesting the INNODUR stainless steel wear strip to be fitted to the leading edge of the auger. This is a replaceable part, further extending machine lifetime.

Highly effective magnetic separation of metallic foreign objects. The Strautmann magnetic system (optional extra) directly mounted at the mixing auger offers optimum health protection for your high-yield cows. The system is mounted such that it is in direct and close contact with the mixed fodder, thus working very effectively.

Manual counter cutters

Two manually adjustable counter-cutters enable the processing of larger quantities of long-fibre fodder such as round and square bales.

Hydraulic counter cutter

The optional two hydraulic counter-cutters can be directly adjusted from the driver seat.

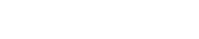

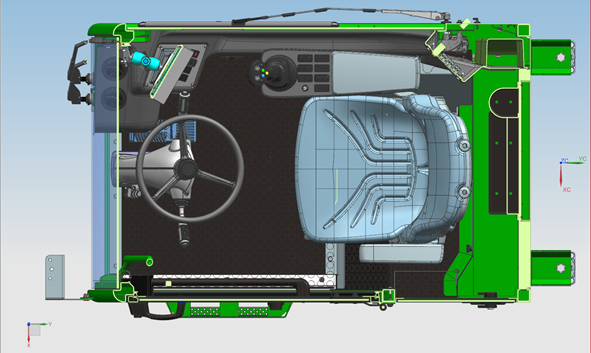

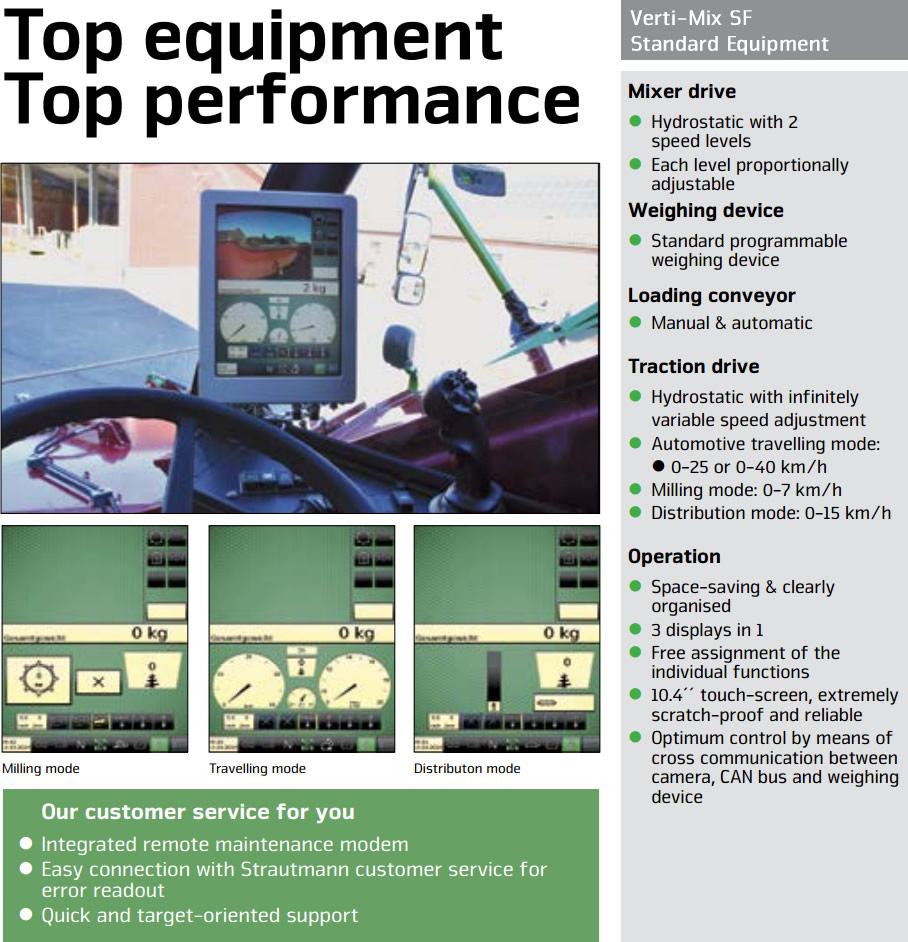

In 2022, Strautmann's self-propelled mixer wagons received a completely redesigned driver's cabin, to optimise towards operator comfort.

The changes provide more space within the cabin, the addition of a variably adjustable armrest, as well as a continuous window in the cabin ceiling has been extended to increase the operators view when milling at a greater height.

A mineral feed funnel can be mounted at the mixing container on request. This makes it easier to fill in smaller quantities of fodder such as e.g. mineral feed or lime.

See Verti-Mix Sherpa model section for control details.

The Strautmann self-propelled one auger mixer has a capacity between 11 and 15 m³, depending on the machine. Easy handling combined with interesting technical equipment make the Verti-Mix SF the ideal entry-level model and the reliable partner for future-oriented enterprises.

Two augers for favorable dimensions and efficient working – that is what the Strautmann Verti-Mix Double SF offers. With its capacity of 14 - 20 m³ and sophisticated technology, this fodder mixing wagon is suitable for larger enterprises with demanding requirements in terms of handling and comfort.

Variable conveyor speeds achieved by means of different motors or direct adjustability enable the fodder discharge width to be adapted as far as right up to directly in front of the feed fence. A unique lattice bar roller as return roller for the crossover conveyor prevents the fodder from piling up between the roller and the conveyor. An optional hydraulic side shift of the conveyor gives added flexibility.

The cleaner and more germ-free the cubicle, the healthier the animals. The ideal litter materials are straw, peat, sawdust and lime. After the mixing process in the container has been finished, the litter is spread up to the head region of the cubicles via the drum – comfortably and reliably for maximum animal comfort and udder health. Only in combination with electrical operation.

Discharge in narrow dead-end feeding passages. For comfortable feeding even in narrow dead-end feeding passages, side doors behind the wheels are being used. The fodder is loosely discharged on one or both sides behind the wheels.

Variable conveyor speeds achieved by means of different motors or direct adjustability enable the fodder discharge width to be adapted as far as right up to directly in front of the feed fence. A unique lattice bar roller as return roller for the crossover conveyor prevents the fodder from piling up between the roller and the conveyor.

For preparation of premixes or central fodder discharge on the feeding table, Strautmann offers a rear centre discharge.

For higher troughs, a 1m long conveyor extension adjustable in height can be mounted at the side of the crossover conveyor.